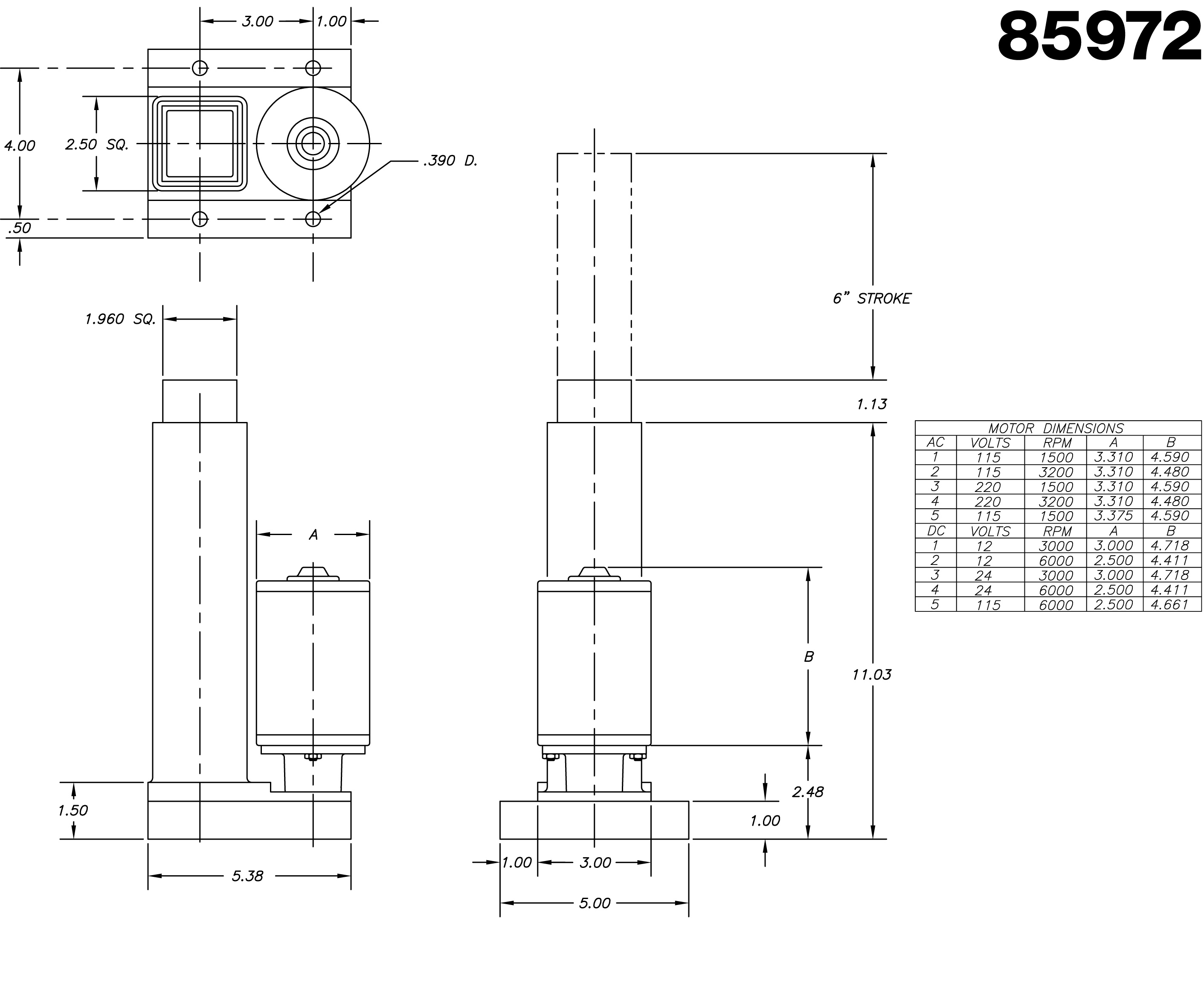

Pedestal Actuator Heavy Duty 85972

The Motion 85972 Pedestal Actuator is a heavy duty design to provide a rigid steel telescoping mechanism along with a base mount in one integrated unit.

The 85972 has a larger mast of 2.500" square for strength and stability. For antirotation and support, the square ground inner tube runs in four teflon impregnated bearing pads welded in the square outer tube. The Motion Ball screw is housed in the inner tube and driven through a 10:1 spur gear reduction in the base. Because of the integral freewheeling at stroke ends, limit switches are not required. Generally the 85972 is recommended for compressive loads up to 500 lbs.

Technical Data Pedestal Actuator 85972 |

||

|

LOAD CAPACITY |

500 lbs. (dynamic) 1000 lbs. (static) Note: 500 lb. load rating is in compression and can be extended in certain applications. |

|

|

|

||

|

STROKE |

Any stroke length may be specified up to 14". Available in inches or millimeters, with no limitation on interim dimensions. |

|

|

|

||

|

STROKE SPEED |

AC Motors: 115, 220 VAC 1500 RPM 115, 220 VAC 3200 RPM |

.55/.45 1.10/.90 |

|

DC Motors: 12, 24 VDC (PM) 3000 RPM 12, 24 VDC (PM) 6000 RPM 115 VDC (PM) 6000 RPM Note: Stroke speeds are in./sec/ with no load speed shown first and 500 lb. load speed shown second. |

.90/.70 1.80/1.35 1.80/1.35 |

|

|

|

||

|

GEAR RATIOS |

10:1 | |

|

|

||

|

MOTORS |

AC Motors: 1) 115 VAC 60/50 Hz., Permanent Split Capacitor Induction, 3.3 diameter, 1500 RPM, intermittent duty cycle (25%), 3 wire, enclosed construction, automatic reset thermal overload protector, UL, CSA recognized, 1.6 amps no load, 1.7 amps at 500 lbs., 18 MFD electrolytic capacitor supplied. 2) 115 VAC 60/50 Hz., Permanent Split Capacitor Induction, 3.3 diameter, 3200 RPM, intermittent duty cycle (25%), 3 wire, enclosed construction, automatic reset thermal overload protector, UL, CSA recognized, 1.3 amps no load, 1.9 amps at 500 lbs., 30 MFD electrolytic capacitor supplied. 3) 220 VAC 60/50 Hz., Permanent Split Capacitor Induction, 3.3 diameter, 1500 RPM, intermittent duty cycle (25%), 3 wire, enclosed construction, automatic reset thermal overload |

protector, UL, CSA recognized, 1.0 amps no load, 1.1 amps at 500lbs., 6 MFD oil filled capacitor supplied. 4) 220 VAC 60/50 Hz., Permanent Split Capacitor Induction, 3.3 diameter, 3200 RPM, intermittent duty cycle (25%), 3 wire, enclosed construction, automatic reset thermal overload protector, UL, CSA recognized, .9 amps no load, 1.3 amps at 500 lbs., 10 MFD oil filled capacitor supplied. 5) 115 VAC 60/50 Hz., Permanent Split Capacitor Induction, 3.8 diameter, 1500 RPM, continuous duty, 3 wire, enclosed construction, automatic reset thermal overload protector, UL, CSA recognized, .6 amps no load, .8 amps at 200 lbs., 10 MFD oil filled capacitor supplied. |

|

|

||

|

MOTORS |

DC Motors: 1) 12 VDC Permanent Magnet Brush, 3.0 diameter, 3000 RPM (no load), intermittent duty cycle (60%), 2 wire, enclosed construction, 2 amps no load, 14 amps at 500 lbs. 2) 12 VDC Permanent Magnet Brush, 2.5 diameter, 6000 RPM (no load), intermittent duty cycle (60%), 2 wire, enclosed construction, 6 amps no load, 24 amps at 500 lbs. 3) 24 VDC Permanent Magnet Brush, 3.0 diameter, 3000 RPM (no load), intermittent duty cycle (60%), 2 wire, enclosed construction, 1 amp no load, 7 amps at 500 lbs. |

4) 24 VDC Permanent Magnet Brush, 2.5 diameter, 6000 RPM (no load), intermittent duty cycle (60%), 2 wire, enclosed construction, 3 amps no load, 12 amps at 500 lbs. 5) 115 VDC Permanent Magnet Brush, 2.5 diameter, 6000 RPM (no load on rectified 115 VAC), intermittent duty cycle (60%), 2 wire, enclosed construction, 1.1 amps no load, 2.5 amps at 500 lbs. |

|

|

||

|

BALL SCREW |

Epicyclic Ball Screw with integral freewheeling at ends of stroke. Screw OD: .653 Screw root dia.: .562 |

Advancement/rev: .187 Materials: heat treated alloy steel with bearing races Rockwell 56C. Efficiency: 90% |

|

|

||

|

GEAR REDUCER

|

Two stage gear type with roller thrust bearing to accommodate ball screw thrust. Base Housing: aluminum alloy Bearings: Ball Drive shaft and pinion supported on sleeve bearings. Gears run on hardened steel shafts. |

Gear materials: steel pinion, nylatron and delrin gears. Motor coupling: 70 durometer neoprene with two heat treated steel inserts. Lubrication: permanently lubricated with synthetic grease. |

|

|

||

|

WEIGHT |

16 lbs. (6 in. stroke with AC motor) 12.1 lbs. (6 in. stroke with DC motor – 3.0 dia. PM) |

|