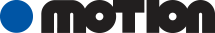

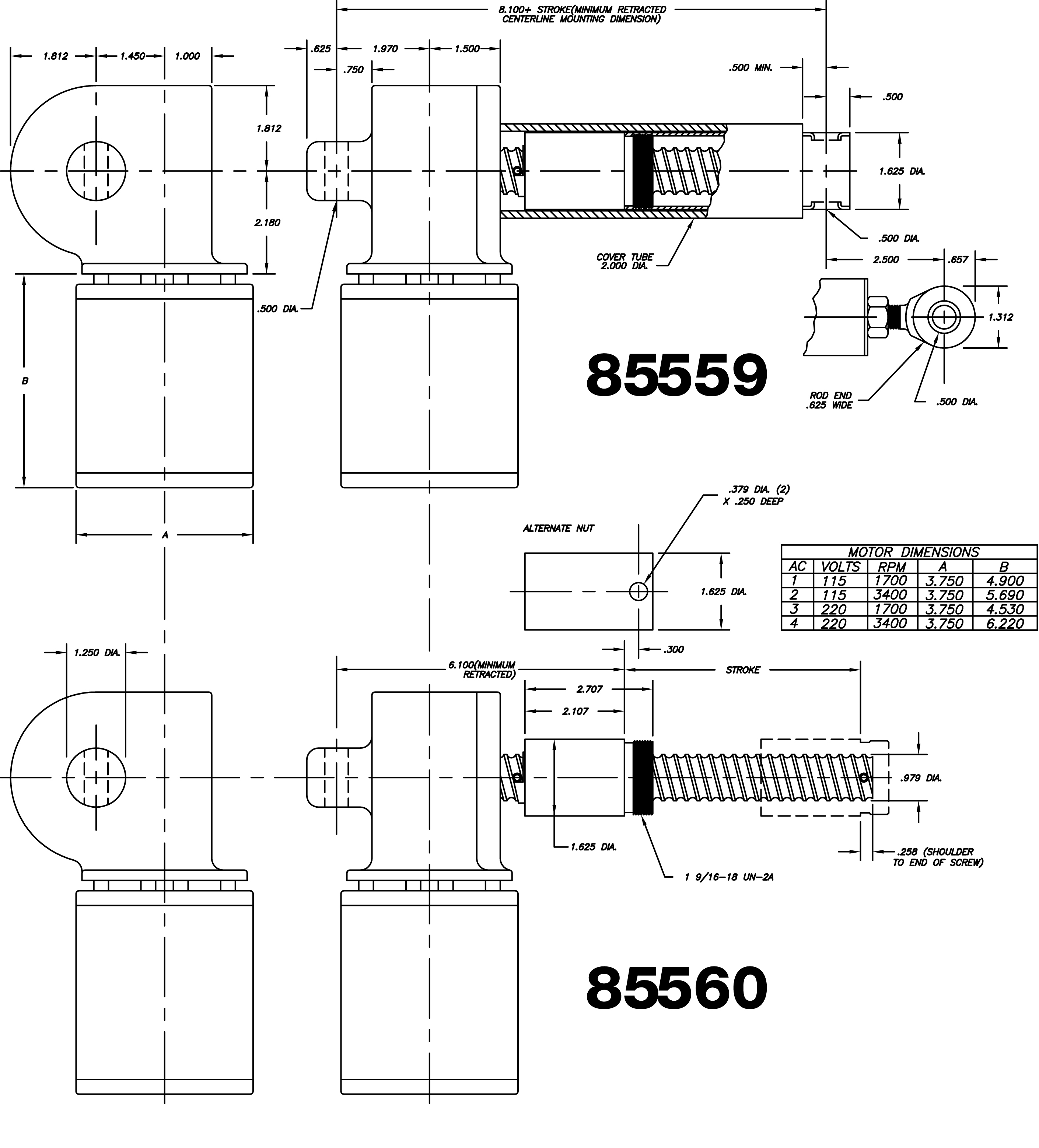

Linear Actuator 85559 / 85560

The Motion 85559/85560 Linear Actuator with load capacity up to 1500 lbs.

It also has integral freewheeling at stroke ends to eliminate limit switches. Both 115 VAC and 220 VAC motors are available. The 85559 uses a translating tube for mounting, while the 85560 is an open screw type unit where attachment is made directly to the ball nut.

|

Technical Data Linear Actuator 85559/85560 |

|||

|

LOAD CAPACITY |

1500 (dynamic) 3000 lbs. (static) |

||

|

|

|||

|

STROKE |

Any stroke may be specified up to 60". Available in inches or millimeters with no limitation on interim dimensions. | ||

|

|

|||

|

STROKE SPEED |

AC Motors: 115, 220 VAC 1700 RPM 115, 220 VAC 3400 RPM Note: Stroke speeds are in ./sec. with no load speed shown first and 1500 lb. load speed shown second. |

26:1 .32/.25 .63/.50 |

52:1

.16/.13 |

|

|

|||

|

GEAR |

26:1, 52:1 | ||

|

|

|||

|

MOTORS |

AC Motors: 1) 115 VAC 60/50 Hz., Permanent Split Capacitor Induction, 3.8 diameter, 1700 RPM, intermittent duty cycle (25%), 3 wire, open construction, automatic reset thermal overload protector, UL, CSA recognized, 2.3 amps no load, 2.8 amps at 1500 lbs., 44 MFD electrolytic capacitor supplied. 2) 115 VAC 60/50 Hz., Permanent Split Capacitor Induction, 3.8 diameter, 3400 RPM, intermittent duty cycle (25%), 3 wire, enclosed construction, automatic reset thermal overload protector, UL, CSA recognized, 4.0 amps no load, 5.5 amps at 1500 lbs., 68 MFD electrolytic capacitor supplied. |

3) 220 VAC 60/50 Hz., Permanent Split Capacitor Induction, 3.8 diameter, 1700 RPM, intermittent duty cycle (25%), 3 wire, open construction, automatic reset thermal overload protector, UL, CSA recognized, 1.1 amps no load, 1. Amps at 500 lbs., 10 MFD oil filled capacitor supplied. 4) 220 VAC 60/50 Hz., Permanent Split Capacitor Induction, 3.8 diameter, 3400 RPM, intermittent duty cycle (25%), 3 wire, enclosed construction, automatic reset thermal overload protector, UL, CSA recognized, 1.2 amps no load, 2.0 amps at 1500 lbs., 17 MFD oil filled capacitor supplied. |

|

|

|

|||

|

BALL DRIVE |

Epicyclic Ball Screw with integral freewheeling at ends of stroke. Screw OD: .979 Screw root dia.: .843 Advancement/rev.: .281 Centerline pin dimension: 2.343 + stroke Nut OD: 1.625 |

Nut mounting: 1 9/16-18 thread. Materials: heat treated alloy steel with bearing races Rockwell 56C. Efficiency: 90% |

|

|

|

|||

|

GEAR REDUCER

|

Single stage worm gear type with 6008 ball bearing to accommodate ball screw thrust. Housing: cast aluminum alloy. Bearings: worm shaft and Ball Drive shaft both supported on sleeve bearing and ball bearing. |

Worm and gear materials: steel worm, delrin gear. Motor coupling: 70 duromenter neoprene with two heat treated steel inserts. Lubrication: permanently lubricated with synthetic grease. |

|

|

|

|||

|

WEIGHT |

85559: 16.8 lbs. (6 in. stroke) | 85560: 15.9 lbs. (6 in. stroke) | |